Chillers are essential equipment in the food and dairy industry. They are used to cool milk and other food products after processing to prevent bacterial growth. This helps to extend the shelf life of the products and improve their safety.

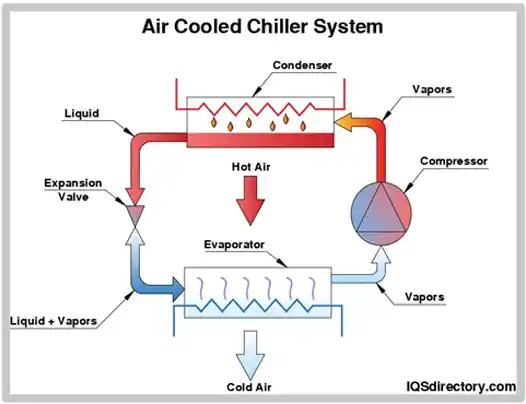

Chillers work by using a refrigerant to transfer heat from the product to be cooled to a surrounding environment. The refrigerant is circulated through a closed loop system, and its state is changed between liquid and gas to absorb and release heat.

which is precisely designed by our Experts. Which used to facilitate Efficient heat exchange from water to a refrigerant in a closed loop system. We offer our chilling plant with highest level of efficiency and functions. We are the leading manufacturers, exporters and suppliers of chilling Systems.

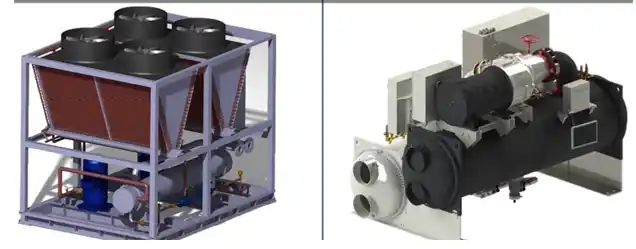

Air-cooled chillers use fans to blow air over a condenser coil. The air removes heat from the coil, which cools the refrigerant inside the chiller. Air-cooled chillers are typically less expensive to install and maintain than water-cooled chillers. However, they are also less efficient and can be noisy.

Air-cooled chillers are typically used in smaller applications, such as commercial buildings and residential homes

Water-cooled chillers use water to cool the refrigerant inside the chiller. The water is pumped through a condenser coil, where it absorbs heat from the refrigerant. The heated water is then cooled in a cooling tower or evaporative condenser. Water-cooled chillers are more efficient than air-cooled chillers, but they are also more expensive to install and maintain

Water-cooled chillers are typically used in larger applications, such as industrial facilities and data centers.